What are Dropped Objects?

First thing's first - what can be classed as a dropped object?

Put simply, dropped objects can be put into one of two categories:

Static Dropped Objects

Static drops refers to any object that falls from its previous position under its own weight (gravity) with no additional force. Failure resulting form corrosion or vibration are the most common static drops incidents.

Dynamic Dropped Objects

Dynamic drops refer to objects that fall due to an applied force. Collisions involving moving equipment and dislodged tools or equipment are the most common drops incidents classed as ‘dynamic’.

So how dangerous are dropped objects?

Let’s look at some staggering stats…

There is a huge issue of under-reporting of Dropped Object incidents throughout the energy sector. The statistics that are available, however, shine a light on the danger and impact dropped object incidents can have. We have put together some of these statistics to highlight the dangers:

America

According to the Bureau of Labor Statistics, an injury caused by a dropped object occurs every 10 minutes in the United States alone – that’s more that 50,000 dropped object accidents every year!

OSHA (Operational Health and Safety Association) claims that on average 140 people are ‘struck by a falling object’ every day in the United States.

In 2016, 255 people died as a result of a falling object, according to the Bureau of Labor Statistics 2016.

Australia

9% of workplace fatalities in Australia in 2022 were due to being hit by a falling object. That’s 16 deaths from Dropped Object incidents, each incident costing AUD23 million in compensation, according to Safe Work Australia, 2022

Safe Work Australia also reported that in 2014, 15,410 serious workers compensations claims were made due to dropped or falling objects.

The Impact of Dropped Objects

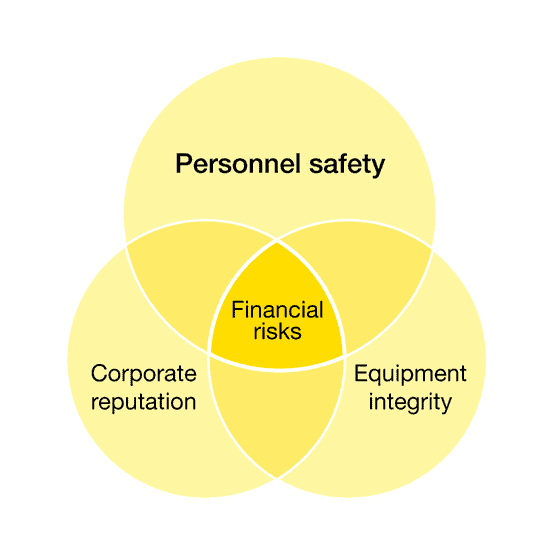

Acknowledging the fourfold threat

Dropped object incidents present a fourfold threat to the safety of personnel, the integrity of equipment, the reputation of the company or businesses, and the financial performance. While safety is always the first priority, the other three factors combine to cause financial losses.

Equipment integrity

A dropped object can strike equipment, leading to the loss of tools and damage to structures. If an incident causes damage to critical equipment, this not only incurs the cost of replacing damaged assets, but may also lead to a temporary suspension of operations, causing further financial losses.

Corporate reputation

Dropped objects do have more far-reaching impacts than just the safety of people and equipment; the negative press coverage that can come from a dropped incident can damage a companies reputation and, in turn, future business prospects.

Financial risks

Again, financial impacts may be the least of a plant manager’s concerns, but the above risks combine to impact the financial standing of a business in different ways – directly or indirectly. Replacing equipment that can be damaged or lost can also be an expensive result of objects falling from height.

Personnel safety

Unarguably the most important impact resulting from a dropped object is personnel safety and the potential for injury or loss of life. Even injuries that are not fatal can have serious ramifications and ongoing issues (including medical expenses, familial trauma and loss of income). There is no excuse for facilities, worksites of businesses in any industry to endanger employee safety due to having inadequate safety measures in place.

According to the National Safety Council, 1 employee death costs US$1.4 miillion. This includes both direct and indirect costs (including lawsuits, compensation, medical expenses, fines and even lost time). It is important to remember that the ‘cost’ of a workplace fatality goes much further than sums on money.

By ensuring you have adequate safety systems installed, dropped object risks can be mitigated before they become issues.

How do items become Dropped Objects?

Looking at the top causes for items falling from height

Dropped object incidents can occur at any time, for any number of different reasons. On worksites – especially those in the energy industry – the likelihood of a dropped object risk occurring is significantly higher. Any location with a large number of potential hazards means there will inevitably be a greater number of risks that could be realised.

Of all the reasons that can cause dropped object incidents to come about, the top ten can be identified as the primary causes.

Oil and gas industries. Panorama view of offshore scaffolders standing on the pipeline and new oil and gas platform installed in the middle of the sea with cloudy sky background.

Improper risk assessment

The failure to adequately identify hazards that could become dropped objects

Risk assessment tools are used to help prevent major hazards – such as dropped objects – from injuring workers. The probability that something is likely to cause injury – combined together with the potential severity of the injury – is classified as a risk. Inadequate acknowledgement, understanding and assessment of risks makes for an unsafe work site. Risks can only be controlled and dealt with through risk assessment.

Human factors

Complacency, human error and neglect can all be avoided

Many of these factors can be prevented or, when not preventable, be rectified before personnel safety becomes an issue. Basic safety training upon the hiring of new employees is a start, yet the evaluation of human factors needs to be an ongoing effort involving all employees. Human factors need to be understood in order for an occupational safety professional to find ways to mitigate risks with ‘stopgap’ measures, preventing accidents before they occur. Human factors are the key cause of nearly half of all dropped object incidents.

Inadequate procedures

Often a result of poor planning and no management of change

Management of change is something that needs to be in place in order to identify and control risk that comes from changes that occur within the workplace. Namely those that may create new or previously unidentified areas of risk. Procedures to prevent risks from occurring in the first instance should also be standard across all work sites.

Poor housekeeping

Hazards that remain from prior tasks

Pre-existing hazards from previous tasks can cause serious damage to personnel, especially because the workers will change and rotate, therefore those who witnessed the damage firsthand may not be the ones who suffer the effects. When good housekeeping practices fall down, and poor housekeeping replaces them, the likelihood of accidents and human error increases.

Collisions & snagging

Moving, lifting and travelling equipment all pose risks

Extra care and caution should be employed when it comes to moving equipment and handling wires. Accidents that cause impacts can also cause objects to fall and generate debris which can, in itself, fall, thus causing further risks. Collisions and snagging risks fall firmly into the category of a dynamic dropped object hazard.

Insufficient inspection & maintenance

Ignoring conditions that are deemed to be unsafe

Regular inspections and planned maintenance repair schedules can help when identifying corrosion, damages, equipment wear-and-tear and structural weaknesses before they move from becoming a hazard to a dropped object risk. Maintenance is required frequently in order to keep equipment, machines and the work environment safe. Lack of, or inadequate maintenance, can lead to dangerous and potentially life-threatening situations.

Redundant, neglected or homemade equipment

Anything that fits into this category must be eliminated immediately

Homemade tools, tethers, dropped object prevention devices and any other equipment used on-site, serves only to increase risks within the workplace. The equipment has not been certified, tested and, in most cases, is a ‘quick fix’, temporary solution which has ended up being left in place long-term.

Inadequately stored tools & equipment

Tethering tools and loose items is critical

Tethering tools is crucial, as when tools become dropped objects, they can be just as dangerous as larger objects (and often more so, as their projected fall track is far harder to predict). Similarly, loose or handheld items of any kind should also be secured, whether to an individual or some form of tool bag, in order to prevent a dropped object incident occurring. When not using certain equipment, it is important that it is stored correctly and appropriately. When tools are not stored correctly, they can present trip hazards, can be kicked from walkways to become dropped objects, and cause further issues.

Failed fixtures & fittings

Failed fixtures can have fatal consequences

Usually occurring in areas of a worksite where asset inspection is difficult or a geographic location prone to extreme weather conditions, failed fixtures can have fatal consequences. Bolted connections are also a form of fitting that, if failure was to occur, would cause a potentially fatal dropped object incident. Bolted connections are produced to more than 85 different industrial standards, depending upon sector, operational and maintenance requirements.

Environmental factors

Wind, sea motion, ice, snow, extreme heat, sand storms – the list goes on

Harsh weather can compromise stability and the security of equipment. These factors can cause increased corrosion, while putting additional pressure on fixtures located at height, and other structural elements that are exposed to harsh conditions. The best way to combat extreme weather is to ensure all equipment is secured with appropriate dropped object prevention solutions.

The science behind it all…

The physics behind dropped objects shed light on the magnitude of the risks

When an item or object falls from height, its initial weight and the distance it falls need to be understood. Even an item that is not what might be considered ‘heavy’ can easily have a fatal impact.

For instance:

A 2kg tool + fall of 5 metres = An impact force of more than 1 Tonne.

By using the Dropsafe interactive DROPS Calculator, you can estimate the severity of an impact a dropped object falling from height may have. Find it here:

Direct impact or deflection

If an item falls without coming into contact with an obstacle of any kind, it will fall straight down. More often than not, however, dropped objects will have their vertical path obstructed. This causes a deflection. The object then becomes a projectile, where it is likely to travel further, faster, and with even more deadly consequences.

According to the National Safety Council, 1 employee death costs US$1.4 miillion. This includes both direct and indirect costs (including lawsuits, compensation, medical expenses, fines and even lost time). It is important to remember that the ‘cost’ of a workplace fatality goes much further than sums on money.

By ensuring you have adequate safety systems installed, dropped object risks can be mitigated before they become issues.

Preventing Dropped Objects

There are a number of solutions you can use to help mitigate and eliminate the risks posed by dropped objects

As mentioned above, dropped objects can occur for a number of reasons. While it is preferential to avoid these happening in the first place (such as not having objects situated at height if not completely necessary), by employing the use of drops prevention solutions on your site or facility, you can prevent hazards from occurring. And, for those that you cannot easily control (such as drops incidents as a result of environmental impact or product failure), the impact they have can be controlled and mitigated.

Overall, by adopting any of these solutions, you can make your worksite safer.

Safety Securing Nets

Netting is used to enclose objects at height to prevent them posing a dropped object risk. Objects situated at height need to be secured in case they should fall. The primary retention (the method by which a fixture at height is secured) can fail for any number of the above reasons. The most likely is the loosening of bolts, screws and mounting brackets due to environmental factors such as corrosion or vibration.

It is important to make sure that all items at height are regularly inspected.

Drops prevention nets are known as ‘safety devices’ as they prevent a fall should the primary or secondary retention fail. There are key things to take into account when selecting a safety securing solution:

- Shock Loading: the Safe Working Load (SWL) of the net needs to be tested to withstand at least the weight of the fixture being secured.

- Integrity: the safety securing net needs to be hardwearing enough to withstand extreme environments and corrosion during its lifespan. Regular inspection is critical.

Take a look at the Dropsafe range of safety securing nets here.

Drops Prevention Barrier

Drops prevention barrier systems attach along the inside of guardrailing on stairways, elevated walkways and raised working platforms, covering the gaps to prevent objects from falling through. These objects can include tools, handheld equipment, and loose fixtures or machinery components.

A robust barrier system will also prevent items that have dropped from potentially ricocheting further, by absorbing the force of a falling object. This is particularly important because items that drop can often ultimately strike a worker from unexpected directions.

When selecting a barrier system, it is important to consider its versatility, as well as its lifespan, durability (to withstand harsh weather, UV, chemicals), and whether the installation is easy and fast. Another key feature of a good barrier system will be little to no maintenance when installed.

It is important to make sure that all items at height are regularly inspected.

Take a look at the Dropsafe Barrier here.

Tool Tethering

As mentioned above, almost half of all drops incidents occur as a result of human factors. The most common ‘human factor’ that causes these incidents is dropped tools or hand-held objects.

By utilising tool lanyards and tethers you can secure any equipment being used at height. Hand tools such as hammers, wrenches and screwdrivers, or their components, may slip from a technician’s grasp and fall through gaps in railings leading to a Drops incident. By taking a proactive approach to preventing dropped tools, facilities have an opportunity to effectively manage the risk of potential harm to their people, assets and businesses’ reputation.

Find out more about tool tethering here, or get in touch to learn more about Dropsafe Tethering range.

Discover more

Explore the full range of Dropsafe products…

Dropsafe are leaders in the Drops Prevention space, and have a product offering to help you make your worksite safer.

Protect your people and mitigate dropped object risks, with Dropsafe.