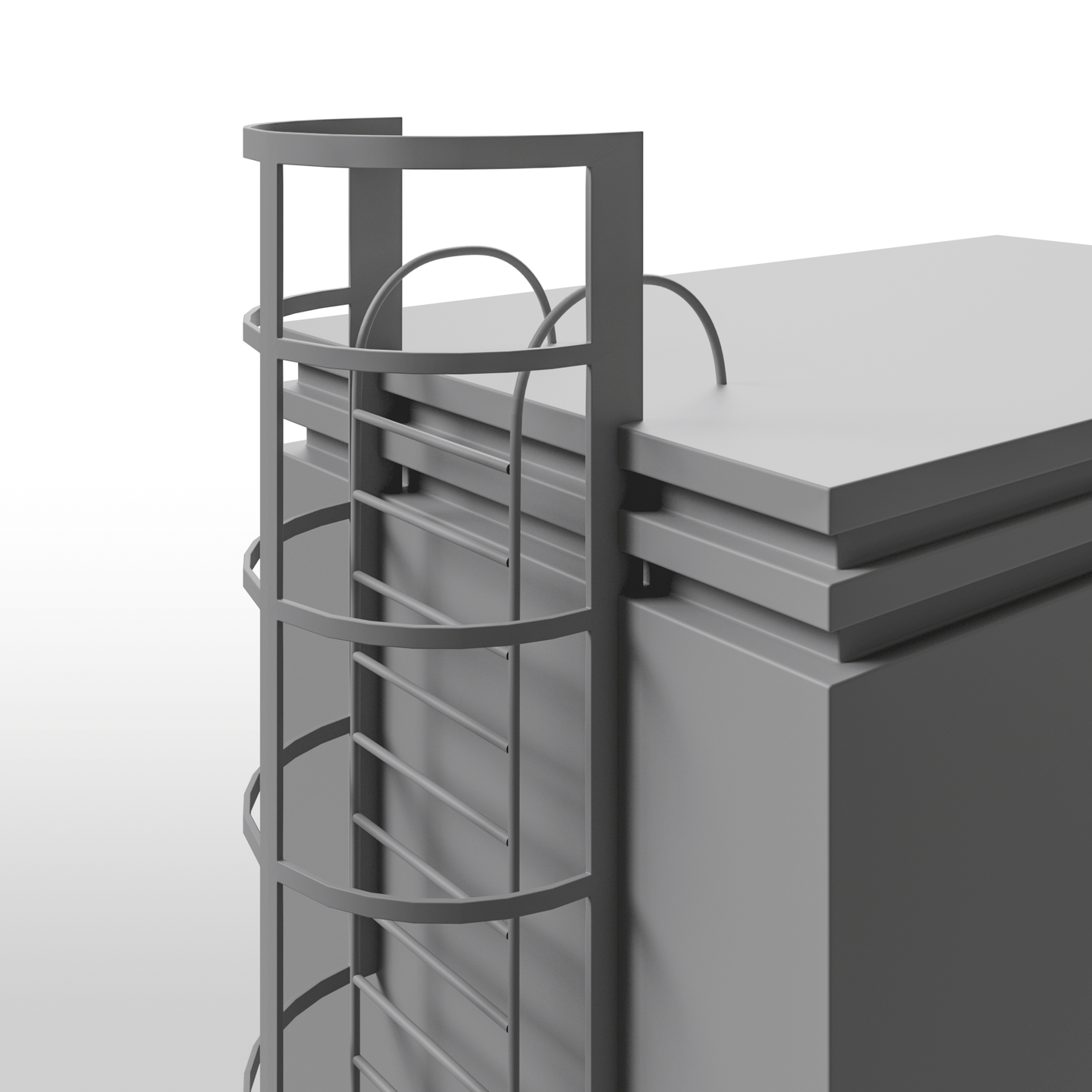

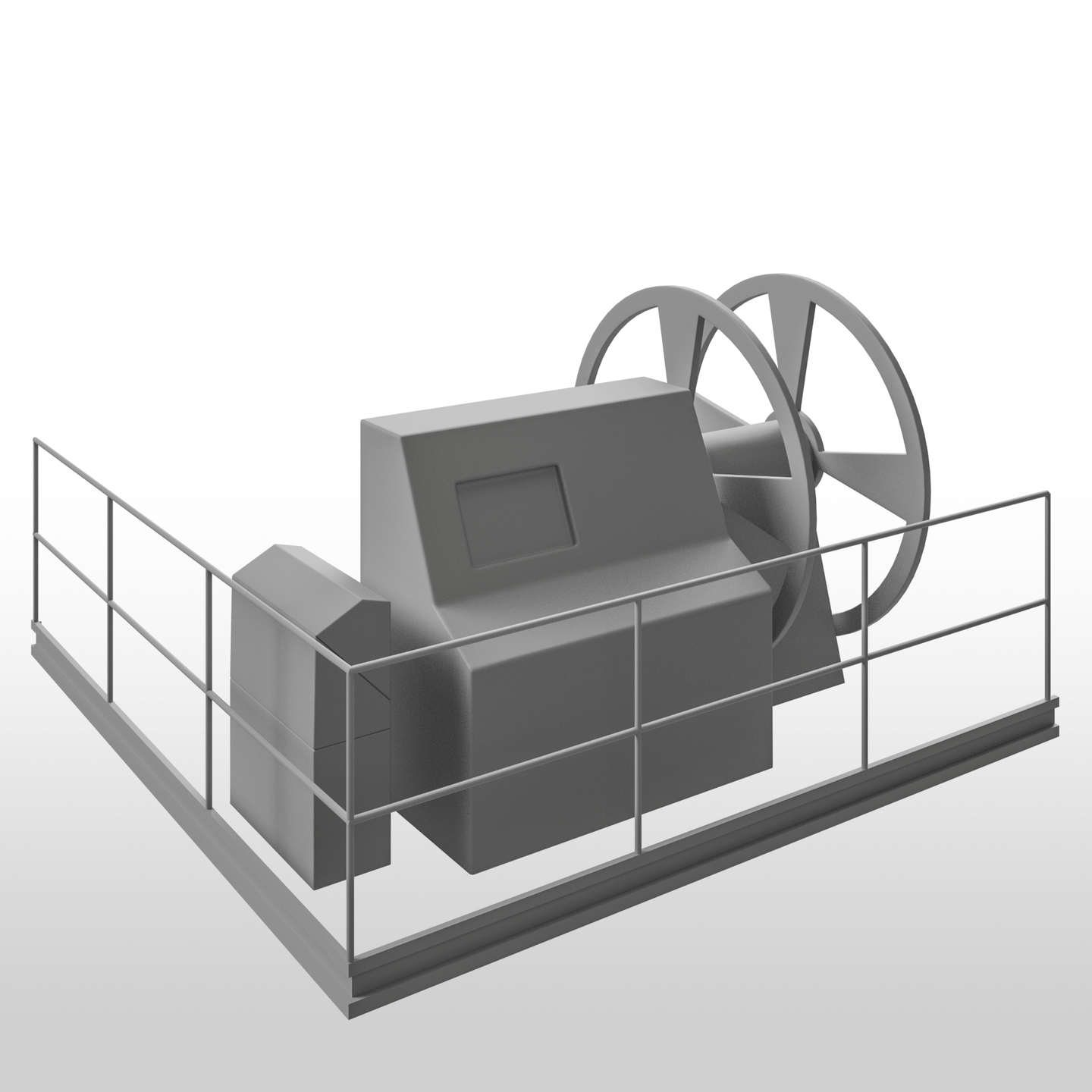

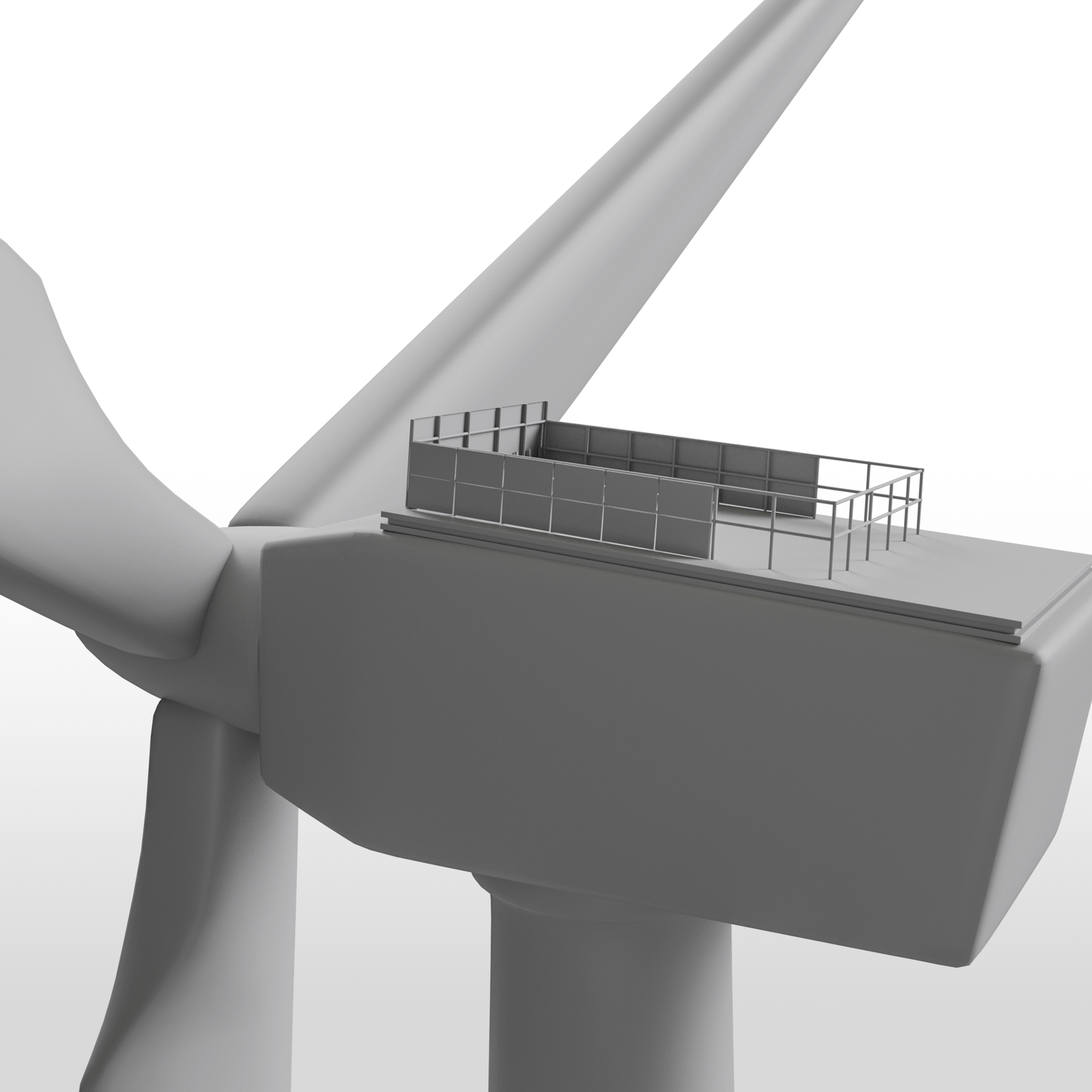

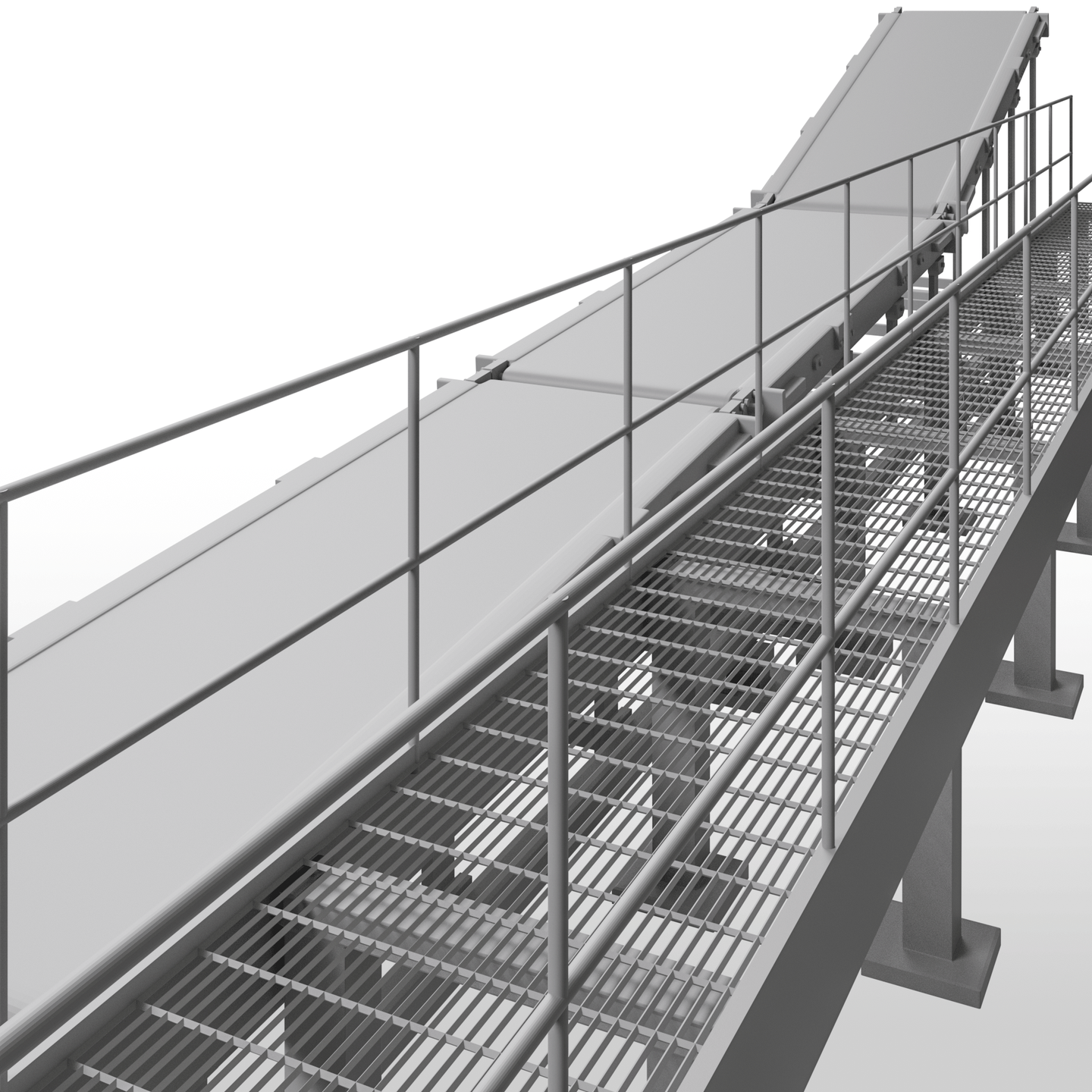

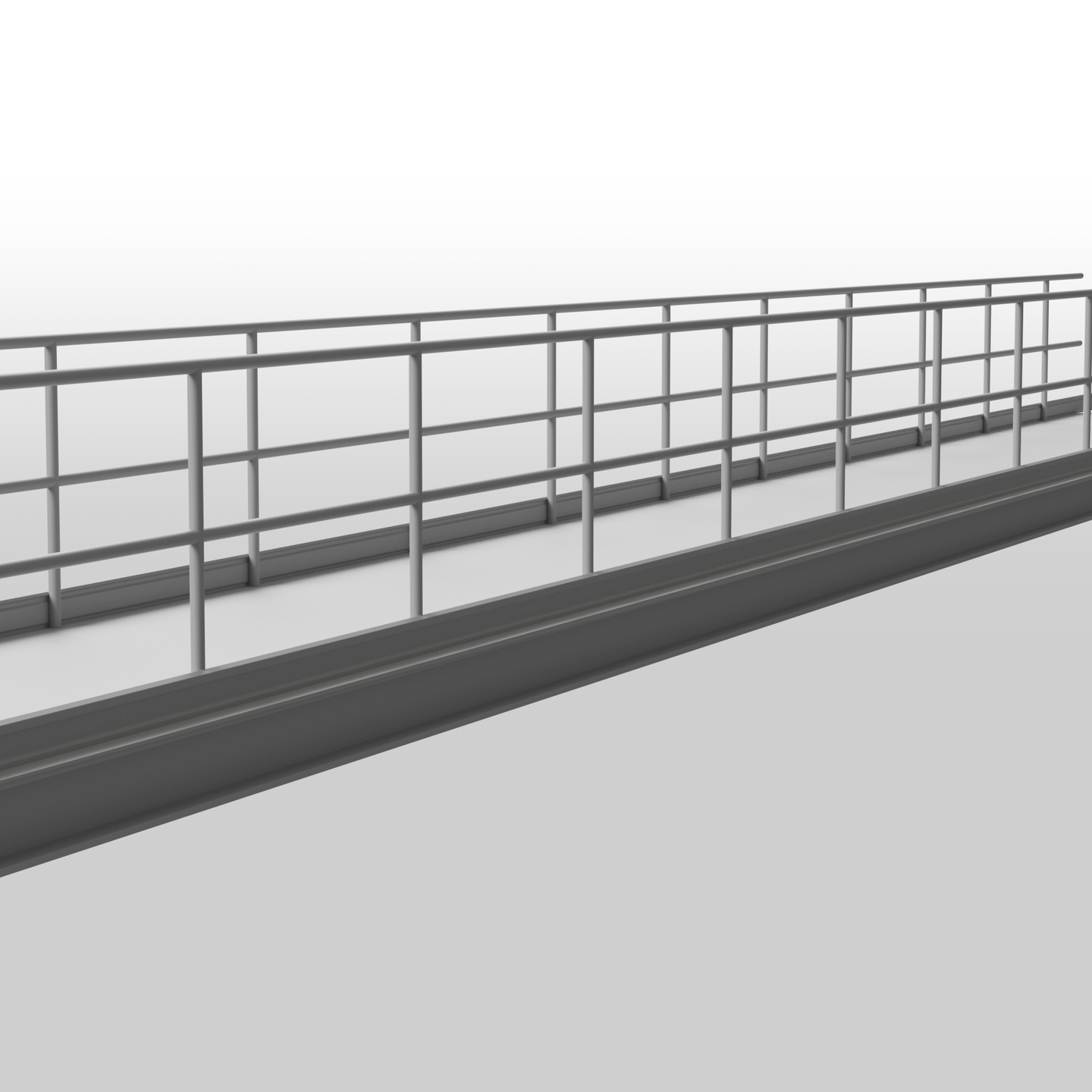

The Dropsafe Barrier is a versatile system designed to prevent items such as tools, handheld devices, or maintenance equipment falling through open guardrailing on walkways, stairways, scaffolding, or elevated work platforms.

The Dropsafe Barrier comes in three different variations, each intended for different environmental applications. Moderate, Extreme or Light. Each version of the Barrier is intended for use in specific locations.

Installation Locations

Benefits

Instant safety solution that is easy to install & prevents objects falling through guardrailing

Designed for harsh environments including a wide temperature range & wind resistance

Simple & effective method of preventing lost time incidents through personnel injury or equipment damage

Cost-effective & maintenance-free system boasting a long service life and reducing industrial waste

Features

Create an account or login for instant access to product information and more

See and download complete product data sheets

View your company's prices and place orders or get fast, efficient quotes

Access tailored Dropsafe online training courses & technical support