Dropsafe has many years of expertise developing safety products to the highest standard. As a result, we know that effective R&D is underpinned by consistent engagement with customers to understand their pain points. This was the case during the development of the Dropsafe Helideck Perimeter Safety Net, when conversations with industry stakeholders pointed to an unresolved issue in the helideck net space: safe and effective annual testing.

Prevailing testing practices for helideck nets are ineffective and may even place personnel at risk. This article examines how helideck nets are currently tested, why this is no longer fit for purpose, and how Dropsafe has developed a new best practice approach.

Drawbacks of existing testing methods

There are two testing methods in widespread use for helideck net solutions – impact tests, and tensile tests.

Impact tests

Impact testing involves removing a sacrificial panel which is included with – but remains separate from – the helideck net. The testers will then drop weights of over 100kg from a metre or more, which can create hazardous situations for personnel. Crucially, the sacrificial panel is usually stored inside, out of the way, meaning it is not subject to any form of degradation from UV or saltwater corrosion and does not offer an accurate representation of the net in situ.

Tensile tests

Tensile tests place the wires or strips of sacrificial pieces under tension to gauge degradation and integrity. Although safer than impact testing, this method is less accurate as it does not test all the parts of the system, such as securing components, frames, ferrules, or bolts. Additionally, performing a tensile test on a strip or wire does not subject the system to the dynamic forces similar to those experienced during an impact.

Impact and tensile tests are therefore less effective than modern best practice approaches, as they do not test the complete system and fail to replicate real-world conditions.

Finally, it should be noted that visual inspections will not uncover developing issues, especially if a helideck net is made from synthetic fibres or metals other than stainless steel – or the net is covered in opaque PVC. The asset owner, in this case, will be unable to assess the level of degradation or rusting occurring.

Developing the testing solution the industry needs

Awareness of these issues has driven a shift towards non-destructive testing methods. With this in mind, Dropsafe developed an Annual Testing Kit and methodology, building on in-depth conversations with customers and global inspection companies to ensure their needs were met while overcoming the testing issues above.

This meant delivering a market-first solution able to accurately determine the condition and safety of the entire solution, testing all components together as a complete system. Crucially, shortfalls in the impact and tensile approaches showed that the new testing methodology needed to replicate the forces experienced during real-world Drops incidents.

Mike Rice, Dropsafe Commercial Director, explains: “Throughout the rigorous testing during the development, we identified the sections of the Perimeter Net that undergo the greatest stress in the event of impact. This was supported by a multitude of tests and data collected using FEA simulations and load cells.

From this, we understood the location and magnitude of peak loads experienced by the system. We continued to test and collect the data using heavier weights until the first signs of any damage were witnessed – not testing to failure. This provided baseline data to inform our recommendations of system replacement times.

We drew on this data and industry knowledge base to develop a Testing Kit that targets the section of the system that experiences the greatest peak load, as well as assessing the impact of environmental conditions over time for each specific helideck. The testing apparatus and methodology was designed to measure these factors against data reference points to make safe and predictive assessments of the Net’s condition over its service life.”

Using the Dropsafe Helideck Perimeter Safety Net Annual Testing Kit

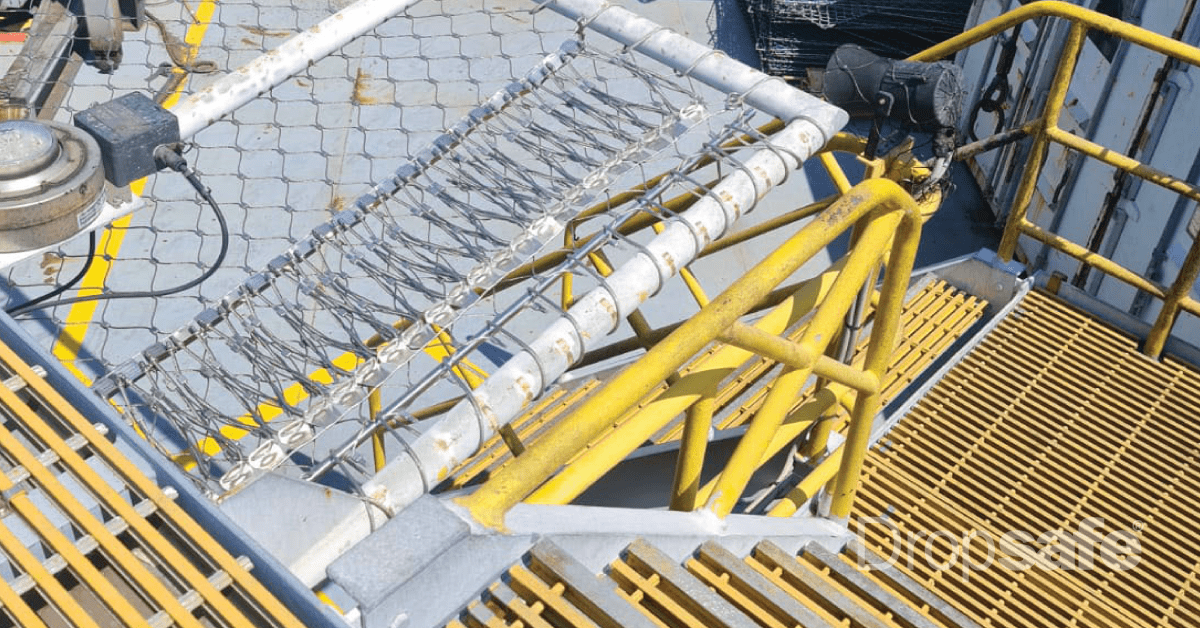

To enable operators and their inspection partners to conduct inspections efficiently and safely with confidence, the Dropsafe Helideck Perimeter Safety Net comes with a CAP 437 compliant testing kit for simple on-site and OEM annual inspections. The kit contains 10 or 25 test samples – one for each year of the solution’s lifecycle – laid on a safe and accessible part of the net which is exposed to environmental stresses such as saltwater, UV radiation, and temperature fluctuations. The testing kit includes all elements of the Helideck Net system, including securing components.

Dan Burman, Business Development Manager, concludes: “Each Annual Testing Kit and test sample includes a unique serial number to ensure full traceability for each Helideck Perimeter Safety Net. The test sample is removed by the customer or inspection company, sent to us via courier, and analysed, allowing us to provide the asset owner and inspection team with a comprehensive scientific test report within days.

“The ongoing reporting provided to the asset owner and inspection companies is fully transparent. It includes photos logging the testing process as well as all data readouts. These reports are logged, updated, and shared with client annually to indicate the performance, condition and remaining safety factor retained by the system using scientific data.

“Ultimately, this provides all parties with peace of mind that the entire system – not just the Net panels – preserves its strength and integrity. An advanced approach to testing was sorely needed – and now this new ‘gold standard’ can address the key issues and weaknesses seen with traditional testing methods”.

To find out more about the Dropsafe Helideck Perimeter Safety Net, get in touch with our experts at info@dropsafe.com or visit the product page here.