The offshore oil and gas industry is fraught with numerous hazards, and among the most insidious is the risk posed by dropped objects. The potential consequences of an object falling from height on an offshore platform are severe, ranging from injuries to personnel, damage to equipment, environmental hazards and even potential fatalities. In an effort to address this critical issue, industry leaders have been actively seeking innovative solutions. One such solution gaining traction is the implementation of secondary retention nets, designed to arrest the fall of objects and minimise the associated risks.

Dropped Objects: A Silent Threat

Offshore oil and gas platforms are bustling hubs of activity where countless tasks are carried out simultaneously. From routine maintenance to complex drilling operations, various activities involve the use of tools and equipment, making the risk of dropped objects an omnipresent concern. Light fixtures, hand tools, and other equipment are often used at considerable heights, exposing the workforce to the danger of falling objects.

The Consequences of Dropped Objects

The consequences of a dropped object on an offshore platform are multifaceted and can be catastrophic. Personnel working below are at risk of injury, and in the worst-case scenario, fatalities may occur. The impact on critical infrastructure and equipment can result in downtime, costly repairs, and delays in production. Furthermore, the potential for environmental harm, especially in sensitive offshore ecosystems, adds another layer of concern.

Secondary Retention Nets: A Paradigm Shift in Safety

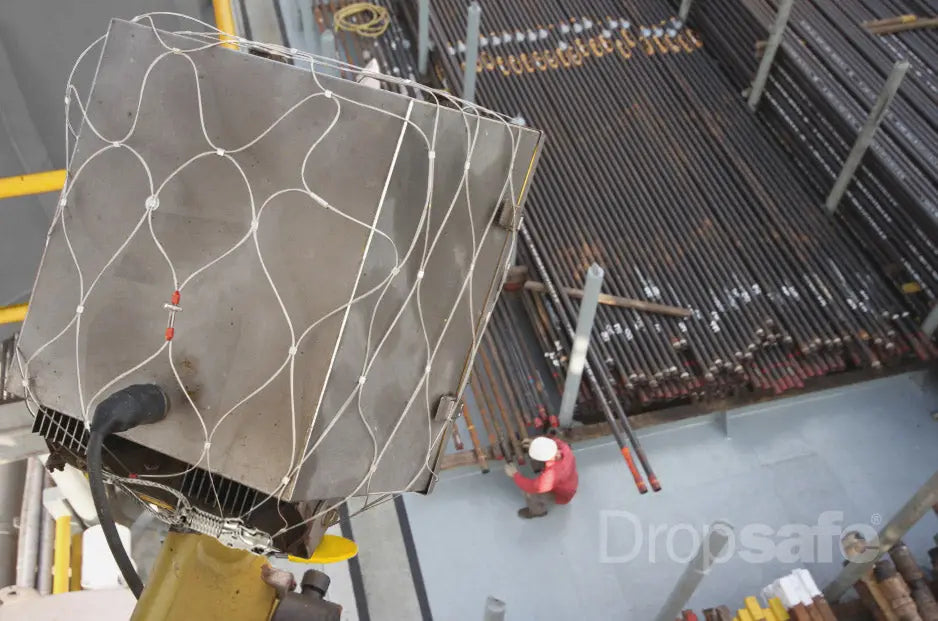

Recognising the gravity of the situation, the industry has been actively pursuing preventive measures to curtail dropped object incidents. Secondary retention nets have emerged as a crucial component in the safety arsenal, providing a robust defense against falling objects. These nets are strategically installed to intercept and arrest objects before they reach the lower decks, offering a comprehensive solution to mitigate the risks associated with dropped objects.

How Secondary Retention Nets Work:

Secondary retention nets are typically constructed from high-strength materials capable of withstanding the harsh offshore environment. These nets are strategically placed at various levels of the platform, forming a protective barrier that intercepts falling objects. The design ensures that the nets do not impede regular operations while providing an effective safety net to capture and secure any objects that may inadvertently fall from height.

Preventing Light Fixtures and Beyond

Light fixtures, being a common fixture on offshore platforms, are particularly susceptible to falling if not adequately secured. Secondary retention nets serve as an effective solution to prevent the peril of falling light fixtures. These nets can be customised to accommodate various types and sizes of objects, ensuring a versatile and comprehensive safety solution. Beyond light fixtures, tools, equipment, and other potential hazards can also be safeguarded by these nets, making them a versatile and vital safety measure.

Advantages of Secondary Retention Nets

Enhanced Personnel Safety

The primary advantage of secondary retention nets is the significant improvement in personnel safety. By preventing objects from falling to lower levels, the risk of injuries and fatalities is substantially reduced, creating a safer working environment.

Protection of Critical Infrastructure

Offshore platforms house intricate and costly equipment. Secondary retention nets act as a protective shield, preventing damage to critical infrastructure and averting the need for expensive repairs and downtime.

Environmental Stewardship

Offshore platforms are often situated in environmentally sensitive areas. The prevention of dropped objects through secondary retention nets contributes to environmental stewardship by minimising the risk of spills, leaks, or other ecological hazards.

Regulatory Compliance

As safety regulations in the offshore industry become increasingly stringent, the implementation of secondary retention nets aligns with compliance requirements. Proactively addressing dropped object hazards demonstrates a commitment to regulatory standards and industry best practices.

Operational Continuity

By mitigating the risks associated with dropped objects, secondary retention nets contribute to operational continuity. Unplanned downtime due to equipment damage is minimided, ensuring that production targets are met efficiently and safely.

Challenges and Considerations

While secondary retention nets offer a compelling solution to the dangers of dropped objects, their implementation requires careful consideration. Factors such as proper installation, regular inspection, and maintenance are crucial to ensuring the effectiveness of these safety measures. Additionally, training personnel on the importance of securing tools and equipment and creating a safety culture that emphasises prevention are integral components of a comprehensive safety strategy.

In the dynamic and challenging environment of offshore oil and gas operations, the danger posed by dropped objects cannot be underestimated. Secondary retention nets represent a groundbreaking approach to mitigating this risk, providing a comprehensive and versatile solution to safeguard personnel, protect critical infrastructure, and uphold environmental responsibility. As the industry continues to evolve, the widespread adoption of secondary retention nets stands as a testament to the commitment of offshore oil and gas companies to prioritise safety and well-being in their operations.