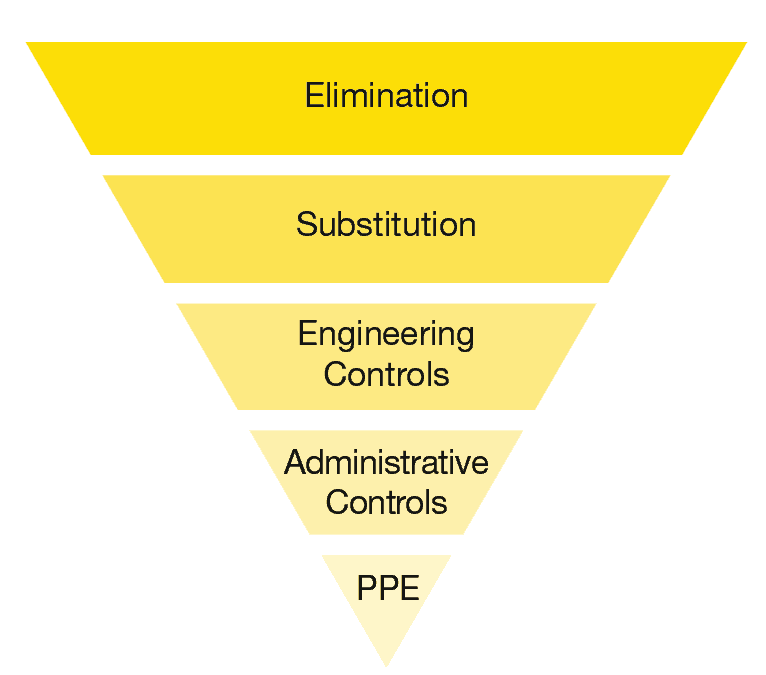

The five-step hierarchy of controls should be the starting point for any strategy focused on Drops prevention

If you’re wondering what steps you need to take to ensure personnel are protected from Drops hazards, you should follow the hierarchy of controls.

What is it? The hierarchy of controls has been described as the basic building block of health and safety procedures across industries such as oil and gas, power generation and manufacturing.

Simply put, the hierarchy of controls shows the critical steps that need to be taken – in order of priority – when tackling health and safety hazards. It should be the starting point for any health and safety strategy and this is especially the case in the context of drops prevention.

The five priorities that make up the hierarchy of controls

1. Elimination:

Are you able to remove the risk? For example, when designing a facility, assess potential overhanging hazards such as lights and speakers. Perhaps not all of these fixtures are necessary. Similarly, in the context of operations, remember that lifting manoeuvres are a major source of Drops incidents. Focussing on minimising lifting where possible should be high on plant managers’ agendas. Consideration should also be given to designing a facility that reduces the number of lifting operations needed.

2. Substitution:

If it’s not possible to completely eliminate a risk, what steps can be taken to ensure it’s minimized? Operators need to consider whether fixtures that pose overhanging hazards could be positioned elsewhere, for example, and whether a different type of lighting could be used.

3. Engineering controls:

Have you installed nets, barrier systems, pouches and ‘red zone mats’, for example? Such equipment is designed to place a physical barrier between Drops and personnel. Examples include using safety securing nets that enclose fittings such as CCTV cameras to prevent them falling in the event their fixtures loosen. Another option is fitting solid barriers onto railings to prevent tools and other object from falling through gaps.

4. Administrative controls:

Have you implemented ‘no-go’ zones? You should also consider developing collision checklists and toolbox talks. Such measures are examples of administrative controls that mitigate Drops by aiming to enforce procedures and reduce human error.

5. Personal protective equipment (PPE):

Providing personnel with PPE represents the last line of defence against Drops. Have you provided PPE to help minimise serious injuries and fatalities if personnel are struck by a falling object?

Important: Take steps to ensure controls are reviewed

It’s vital you assess the effectiveness of the control methods you implement and adjust as required.Ensure controls do not create new hazards. For example, wearing PPE could contribute to other hazards, such as heat stress, so it is important to conduct a review and consider whether other controls methods are possible or if additional precautions are needed. It’s vital you monitor both the hazard and the control method to ensure the control is working effectively and that exposure to the hazard is reduced or eliminated.

Monitoring controls: A checklist

1. Have the controls effectively eliminated or reduced worker exposure?

2. Have any new hazards been created?

3. Are new hazards appropriately controlled?

4. Are any other methods required?

5. Are workers trained on the control methods?

6. What else can be done to eliminate or reduce exposure?

7. If there is a change at the workplace, does this impact the hazard or the control methods?