Shop Dropsafe online

You can buy Dropsafe products online, as well as get quotes and find out much more about our whole range.

Products

Trusted by industry leaders

Events

At Dropsafe, we regularly attend tradeshows & industry events. We will be exhibiting at a number of exciting shows throughout 2025 in the American, European and Asia-Pacific regions.

Please feel free to get in touch to book a meeting.

News

The fourfold threat posed by dropped objects

The fourfold threat of dropped objects is a combination of equipment integrity, personnel safety,...

Read this article

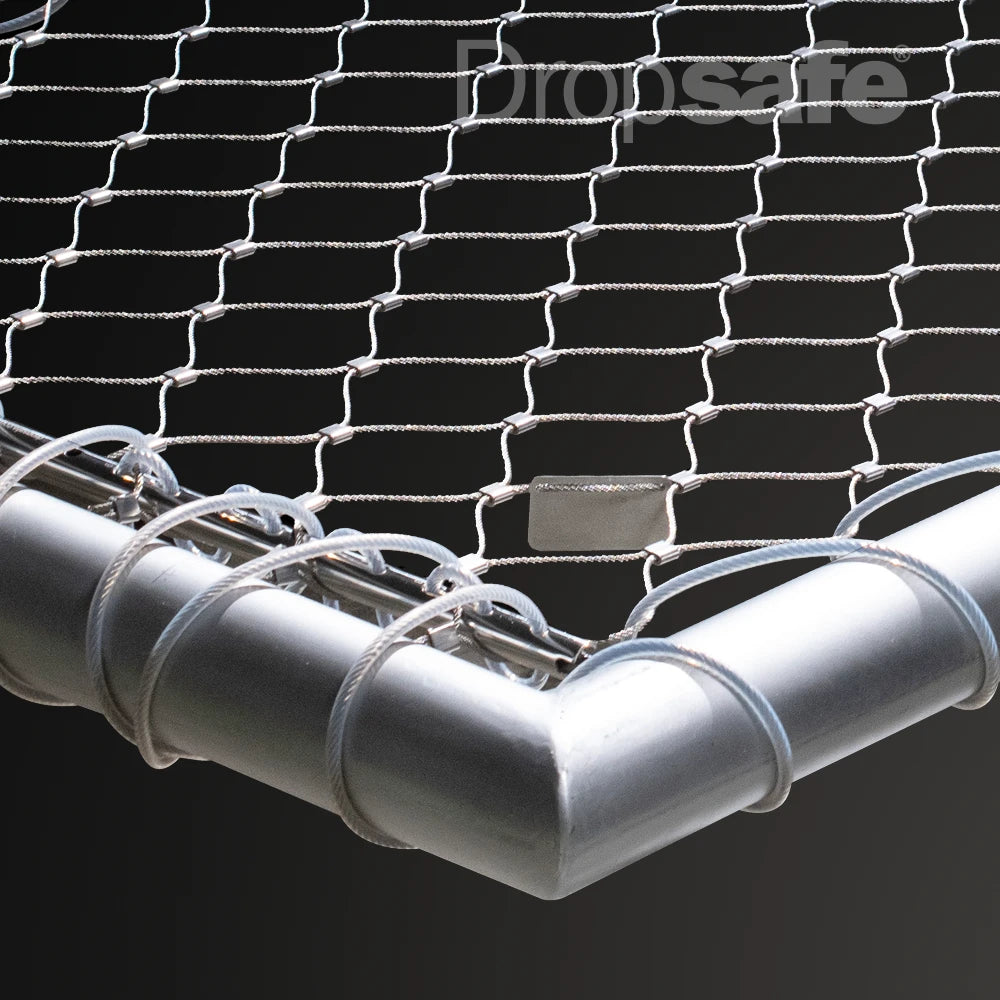

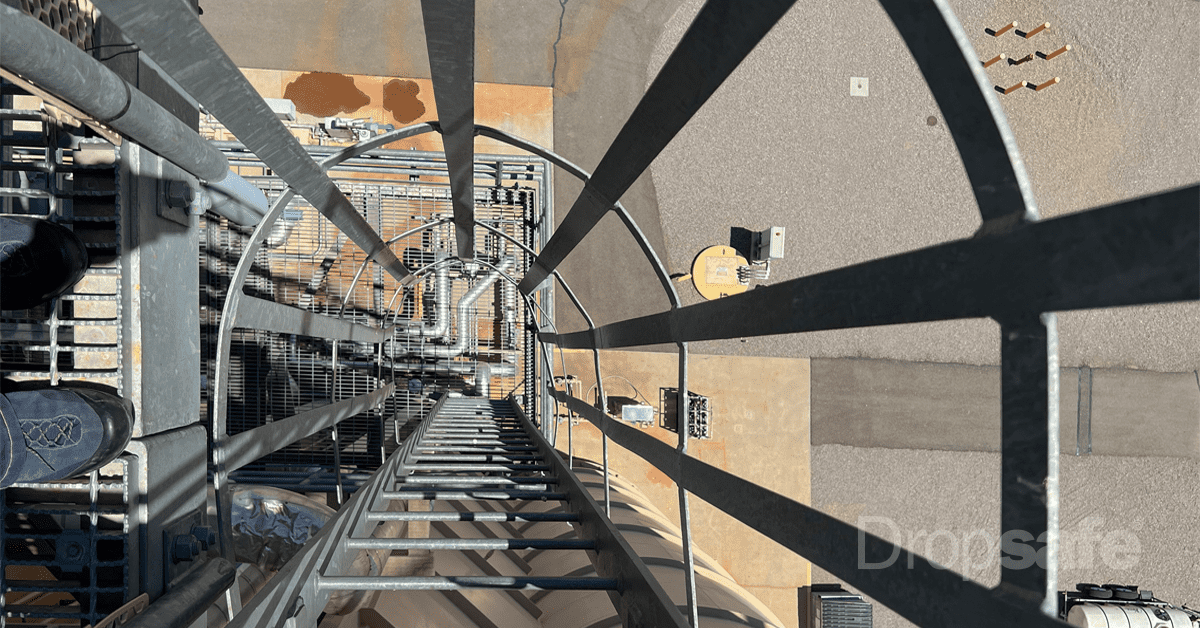

Secondary retention Nets in offshore oil and gas to prevent drops

The offshore oil and gas industry is fraught with numerous hazards, and among the most insidious ...

Read this article

Key sustainability questions to ask your safety supplier

There are four key questions that you can ask to ensure your supplier’s commitment to sustainabil...

Read this article