Key sustainability questions to ask your safety supplier

Across many industries, site operators are pushing for more sustainable approaches to safety. There is only so much you can do to reduce your own environmental impact, however, before you need to look to your supply chain. A large proportion of the environmental impacts of safety solutions, from raw materials use to CO2 emissions, come from manufacturing and transport.

You need suppliers that can match your commitment to sustainability, but it isn’t always easy to distinguish between competing claims made by suppliers. There are four key questions that you can ask to ensure your supplier’s commitment to sustainability aligns with your own.

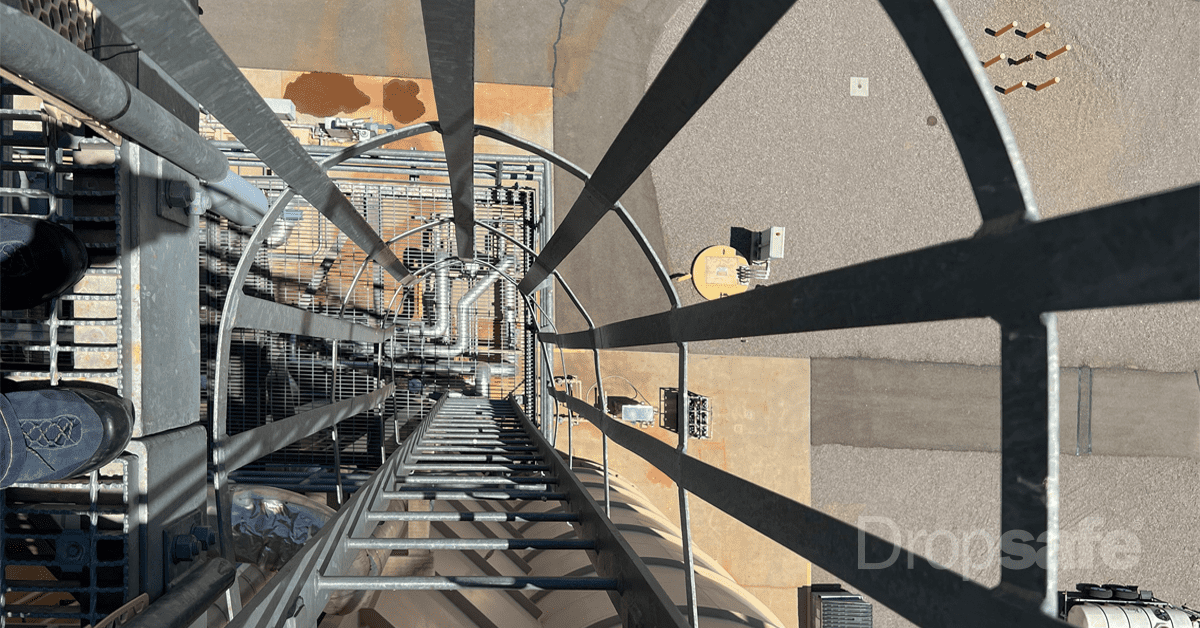

1. What is the lifespan of the chosen solution?

Sustainability-focused safety solution providers will design products with long-term environmental impacts in mind. Durable safety products will spread their CO2 and materials costs over decades. In contrast, single use consumable products such as plastic mesh netting will need to be regularly replaced, while contributing significant volumes of waste to landfill or, worse, fragile marine environments.

Mike Rice, Dropsafe Commercial Director, says: “At Dropsafe, we all care about the environment. We know that to support the adoption of safe, sustainable solutions, there needs to be very little cost-consequence to designing products with a reduced environmental impact Technological changes over the last 20-30 years have allowed us to develop cost-effective products that last longer while integrating key learnings from operators, helping them meet their sustainability ambitions.”

2. Is manufacturing handled in-house?

Safety solution providers may make claims about the sustainability of their products. Without oversight of their manufacturing supply chain, however, the credibility of these claims is open to question. If a safety solution provider owns their manufacturing facilities, operators can be more confident that strict sustainability and safety standards are adhered to, making carbon offsetting goals more realistic.

Reflecting on the process of designing and manufacturing the Dropsafe TrisafeTM Carabiner, Rice explains: “When we redesigned the Carabiner, we used the latest manufacturing processes. Instead of traditional CNC machining, a subtractive method leading to wasted steel, we used high-tech Metal Injection Modelling, ensuring that material waste is minimised.”

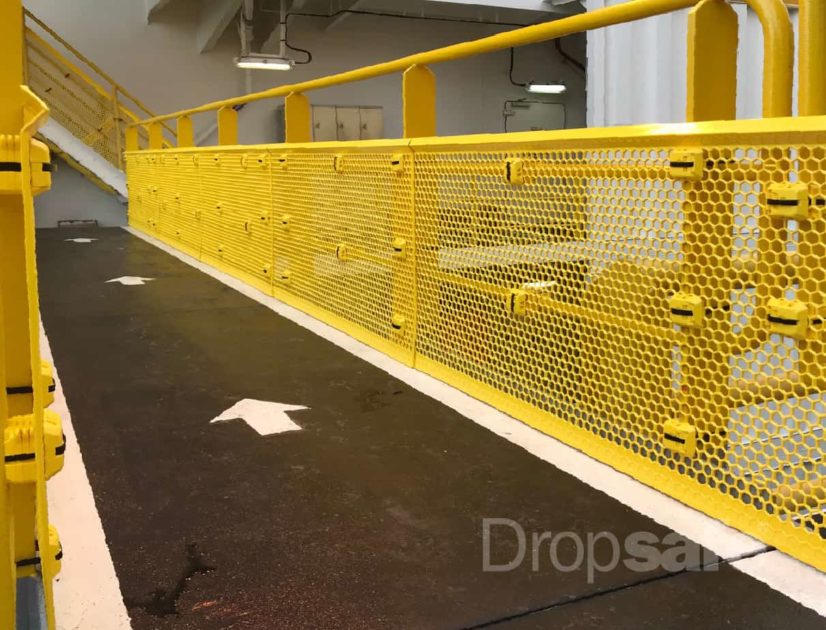

3. What happens to the solution at the end of its life?

Operators should consider sustainability of safety solutions throughout the overall service life of the product. While most stainless-steel safety products can be recycled, not all polymer-based solutions can be, leading to increased waste and CO2 generation. Crucially, not all safety providers have established processes in place to help operators easily recycle their solutions at end of life, placing the burden onto the customer.

Rice says: “Safety suppliers should proactively remove obstacles for operators who are seeking to adopt more sustainable practices. Our customers can send us their Barrier systems at the end of the lifecycle, and we will take care of recycling the high-grade polymer at no extra cost.”

4. How is the solution shipped?

Operators should consider the wider supply chain behind a chosen solution when assessing the sustainability of safety solutions, as packaging and logistics are key factors in minimising waste and carbon emissions. Sustainability-minded solution providers will ensure that the product is shipped with minimal packaging, and that the packaging can be recycled.

Additionally, as shipping accounts for over 3% of carbon emissions, pre-shipping solutions in bulk to a global distributor network is key to minimise long-haul voyages, while reducing lead time for buyers.

Rice comments: “Dropsafe provides its Barrier system with different packing options, ensuring that distributors can chose a packaging configuration which matches their sustainability objectives. We recognise that reducing the carbon emissions of a solutions starts far before the customer receives the product, which is why we aim to minimise the number of journeys undertaken when shipping our solutions to our global distributor network.”

Sustainability is increasingly climbing the agenda in many industries. Operators can play a crucial role in cementing sustainable approaches to safety at their facilities, and within their organisations. Fundamentally, though, sustainability starts with durable products, designed with lifetime environmental costs factored in, from shipping to recycling. By asking the above questions, operators can identify these solutions and build safety strategies which will make sense in a net-zero world.

To find out more about how Dropsafe can help you make your safety strategy more sustainable, get in touch at info@dropsafe.com